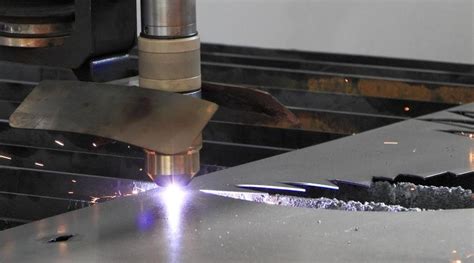

about sheet metal fabrication In this section we’ll cover the best practices to follow when designing for sheet metal bending and laser cutting ー the two sheet metal fabrication services we offer. We’ll begin . See more Tamper-resistant junction box for compact UniFi Dome and Turret cameras that enhances mounting durability, aesthetics, and ease of maintenance. Supports flat surface, pole and pendant mounting Includes side and rear 3/4" conduit entrances

0 · types of sheet metal fabrication

1 · sheet steel fabricators near me

2 · sheet metal fabrication shops near me

3 · sheet metal fabrication near me

4 · sheet metal ductwork fabrication near me

5 · professional sheet metal fabrication

6 · custom sheet metal near me

7 · custom sheet metal fabrication near me

Precast underground junction boxes protect and provide easy access. They are available in various sizes and shapes with or without knockouts. Features & BenefitsAn SWA Cable Junction Box is a general purpose junction box suitable for all surface applications. It is manufactured from impact, corrosion and UV resistant glass reinforced .

Get an introduction to sheet metal fabrication. This section explains the sheet metal fabrication process, how precision sheet metal fabrication differs, the main advantages and disadvantages, as well as its common applications. How does sheet metal fabrication work? There are several different ways to . See moreIn this section, we’ll cover and compare fourteen different types of sheet metal fabrication including cutting, forming, stamping, holemaking and threading. See moreThere are numerous ways of effectively cutting through sheet metal. This section will briefly cover the many different approaches to cut through sheet metal, split into two key . See moreIn this section we’ll cover the best practices to follow when designing for sheet metal bending and laser cutting ー the two sheet metal fabrication services we offer. We’ll begin . See more

During the fabrication process, the sheet metal is usually first punched and cut in different ways and then followed by forming processes to make a nearly finished and realized . See more What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different .

Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . What is sheet metal fabrication, exactly? It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms.

At its core, sheet metal fabrication involves transforming flat metal sheets into functional components. This process combines a variety of cutting, forming, and assembling techniques to create everything from intricate electronic enclosures to large industrial frameworks.Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets. Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, . Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.

Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional components and structures through cutting, .

types of sheet metal fabrication

sheet steel fabricators near me

Sheet metal fabrication is the process of transforming sheet metal (< 1/4” thick) into finished products, structures, and components. From household appliances to transportation, commercial equipment to construction, sheet metal fabrication is critical to modern manufacturing.Get an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings.

What Is Sheet Metal Fabrication? Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . What is sheet metal fabrication, exactly? It’s the process of transforming flat sheets of metal — like aluminum, steel or stainless steel — into desired shapes and forms. At its core, sheet metal fabrication involves transforming flat metal sheets into functional components. This process combines a variety of cutting, forming, and assembling techniques to create everything from intricate electronic enclosures to large industrial frameworks.

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high precision and durability, especially for end-use applications like chassis, enclosures, and brackets. Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, . Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.

Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional components and structures through cutting, .

sheet metal fabrication shops near me

electric lunch box soft boiled egg

We are always looking for experienced, quality CNC machinists. Apply online today! United CNC Machining is a leading manufacturer of prototype and CNC machined components.

about sheet metal fabrication|sheet metal fabrication shops near me